Various ID card printing issues cause ID card printing output to be substandard to requirements. The following recommendation may be helpful to those who find the edges of their card printed too lightly.

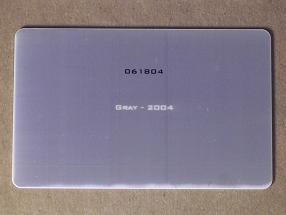

Light edges on the bottom of this card indicate that there is not enough printhead pressure on the bottom edge of the card. This problem can also be caused by defective card stock. To determine if the cause is the card stock, rotate the cards end for end in the card input hopper. If the light edge moves to the opposite side of the card the cause is bad card stock and not uneven printhead pressure.

To correct this problem either lower the end of the printing edge that is towards the front of the printer or raise the end of the printing edge that is towards the back of the printer. Our Head Pressure Adjustment page will walk you through this procedure.

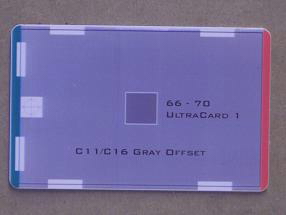

Light edges on the top of this card indicate that there is not enough printhead pressure on the top edge of the card. This problem can also be caused by defective card stock. To determine if the cause is the card stock rotate the cards end for end in the card input hopper. If the light edge moves to the opposite side of the card the cause is bad card stock and not uneven printhead pressure.

To correct this problem either raise the end of the printing edge that is towards the front of the printer or lower the end of the printing edge that is towards the back of the printer. Our Head Pressure Adjustment page will walk you through this procedure.

Please consult with the ID card integrator technical support area where you purchased your printer to obtain assistance for your specific printer issue prior to adjustment. For information about the Fargo DTC550 and current Fargo printers, contact our ID Card experts at 888-485-4696.